| Interface | Profisafe (Profinet IO) TIA |

| Speed | Real Time (RT), Isochronous Real Time (IRT) |

| Profile | Profinet IEC 61158/61784, Profisafe V2.4 |

| Diagnostics | Memory, F-parameter, Device, Parameter, Scaling, Supply voltage, Preset, Velocity |

| Features | Device exchange without programming, Fast Start Up, Media redundancy possible (MRP), Firmware update via Profinet, Programming via Profinet |

| Transmission Rate | 10 / 100 Mbit |

| Interface Cycle Time | ≥ 250 µs |

| Line length (max between two subscribers) | 100 m |

| Transmission Technology | 100 Base-TX |

| Programming Functions | Resolution, Counting direction, Preset, Gate time |

| Output Driver | Ethernet |

| Supply Voltage | 9 – 36 VDC |

| Power Consumption | ≤ 3 W, switch-on current < 500 mA |

| Reverse Polarity Protection | Yes |

| Short Circuit Protection | Yes |

| EMC: Emitted Interference | DIN EN 61000-6-4 |

| EMC: Noise Immunity | DIN EN 61000-6-2 |

| MTTF | 162 years (EN ISO 13849-1) |

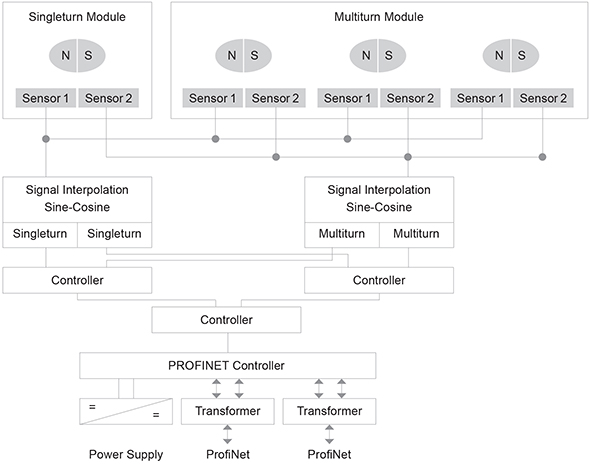

| Technology | Magnetic |

| Resolution Singleturn | 13 bit |

| Resolution Multiturn | 12 bit |

| Multiturn Technology | Magnetic Gearing (no Battery) |

| Accuracy (INL) | ±0.2 % (with reference to one revolution) |

| Code | Binary |

| Cycle Time Base Sensor | 1 ms |

| Protection Class (Shaft) | IP66/IP67 |

| Protection Class (Housing) | IP66/IP67 |

| Min Temperature | -40 °C (-40 °F) |

| Max Temperature | +85 °C (+185 °F) |

| Storage Temperature | -40 °C (-40 °F) – +85 °C (+185 °F) |

| Humidity | 98% RH, no condensation |

| Salt mist test | Test Kb according to IEC 60068-2-52 |

| Housing Material | Aluminum |

| Housing Coating | No Coating |

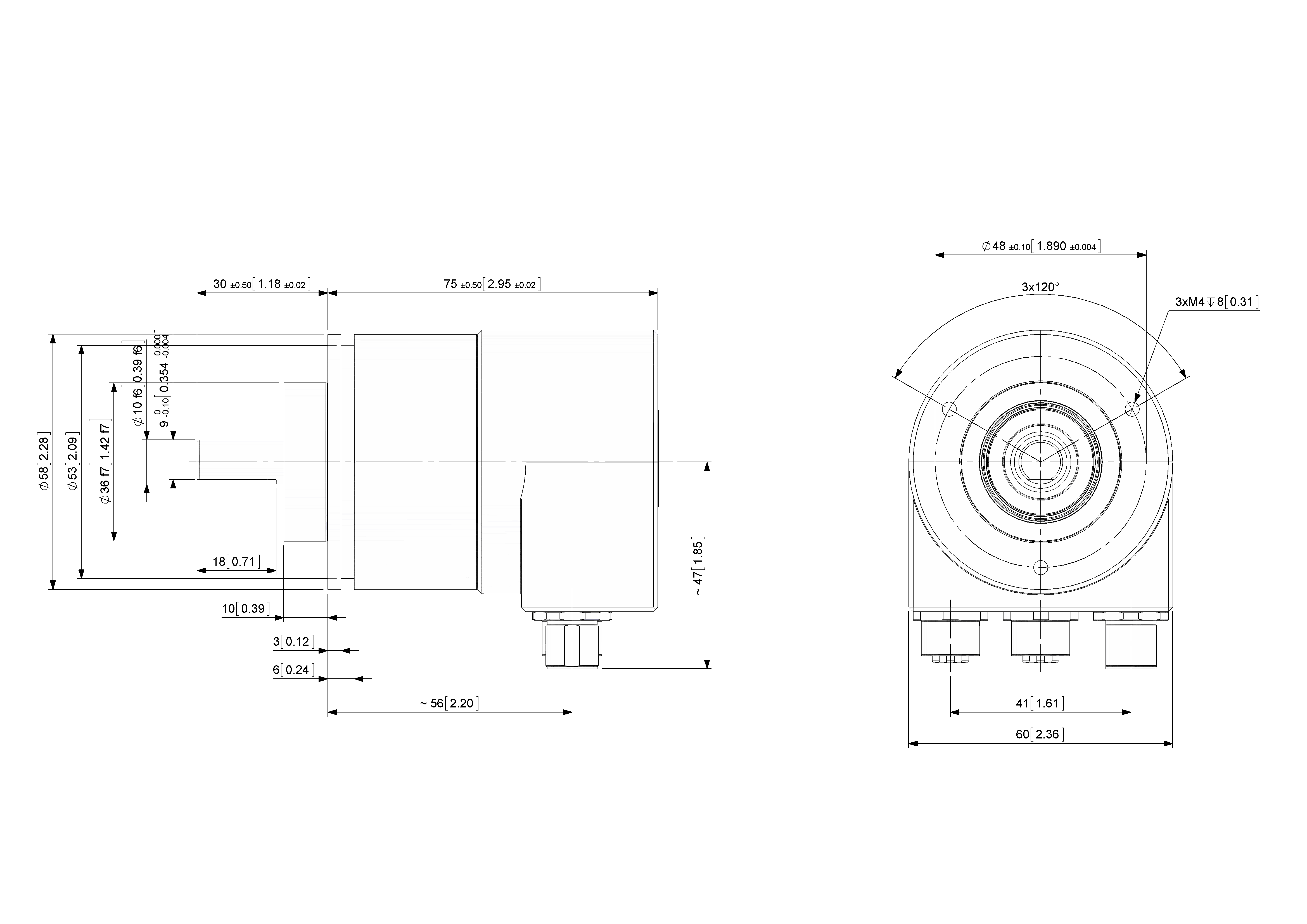

| Flange Type | Clamp, ø 58 mm (L) |

| Flange Material | Aluminum (3.2315) |

| Flange Coating | No Coating |

| Shaft Type | Solid, Single Flat, Length = 20 mm |

| Shaft Diameter | ø 10 mm (0.39") |

| Shaft Material | Stainless Steel V2A (1.4305, 303) |

| Max. Shaft Load | Axial 250 N, Radial 250 N |

| Minimum Mechanical Lifetime(10^8 revolutions with Fa/Fr) | 10 (250N/250N) |

| Rotor Inertia | ≤ 20 gcm² [≤ 0.11 oz-in²] |

| Max. Angular Acceleration | 10^5 rad/s^2 |

| Friction Torque | ≤ 8 Ncm (11.32 oz-in) @ 500 rpm |

| Max. Permissible Mechanical Speed | ≤ 1000 1/min |

| Shock Resistance | ≤ 50 g (11 ms, EN 60068-2-27) |

| Vibration Resistance | ≤ 25 g (10 Hz – 2000 Hz, EN 60068-2-6) |

| Length | 75 mm (2.95") |

| Weight | 450 g (0.99 lb) |

| Connection Orientation | Radial |

| Connector 1 | M12, Male, 4 pin, a coded |

| Connector 2 | M12, Female, 4 pin, d coded |

| Connector 3 | M12, Female, 4 pin, d coded |

| Safety Certificate | 4479913172909 |

| Safety Integrity Level | SIL CL 2 |

| Safety Performance Level | PL d |

| Safety Category | Cat 2 |

| MTTFd (EN ISO 13849-1) | 162 years |

| Intended Time of Usage (EN 61508 and EN 62061) | 20 years |

| HFT (EN 61508 and EN 62061) | 0 |

| SFF (EN 61508 and EN 62061) | 92.2% |

| PFHd (EN 61508 and EN 62061) | 9.889*10-8 1/h |

| Safety Input Data (point of view PLC) | 2 byte status 4 byte position data 2 byte speed data |

| Tolerance of the internal position monitoring | 1.5% (with reference to one revolution) |

| Internal updating time of the position value | 1 ms |

| Internal updating time of the velocity value | 1 ms |

| DCavg (EN ISO 13849-1) | 86.1% |

| Online Data Sheet Version | Version 1, Date 20160115 |

| Certified Data Sheet Version | See download section for the certified data sheet. Version 1, 20160114 |

| Certified Organization | FRABA B.V. , Jan Campertstraat 11, NL-6416 SG Heerlen |

| Company Address | FRABA GmbH, Zeppelinstraße 2, 50667 Cologne, Germany |

| Product Life Cycle | Discontinued |

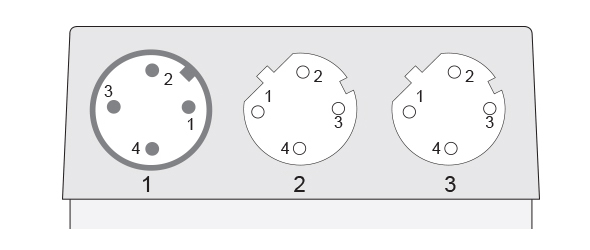

| Signal | Connector | Pin Number |

|---|---|---|

| Power Supply | 1 | 1 |

| Not Connected | 1 | 2 |

| GND | 1 | 3 |

| Not Connected | 1 | 4 |

| Tx+ | 2 | 1 |

| Rx+ | 2 | 2 |

| Tx- | 2 | 3 |

| Rx- | ||

| 2 |

| 4 |

| Tx+ | 3 | 1 |

| Rx+ | 3 | 2 |

| Tx- | 3 | 3 |

| Rx- | 3 | 4 |